Verpatex GmbH - Packaging Technology

We present ourselves as the successor company to Nentwig Verpackungstechnik. We are a young and innovative company that reacts flexibly to your wishes.

Our seat is in Siemensstr. 27 in 52152 Simmerath in the halls of Emotec GmbH. This is where we manufacture our systems in the extension built in 2022.

Our employees and cooperation partners bring enormous knowledge in the field of packaging technology. Due to our age structure, we combine a wealth of experience with modern design and manufacturing options.

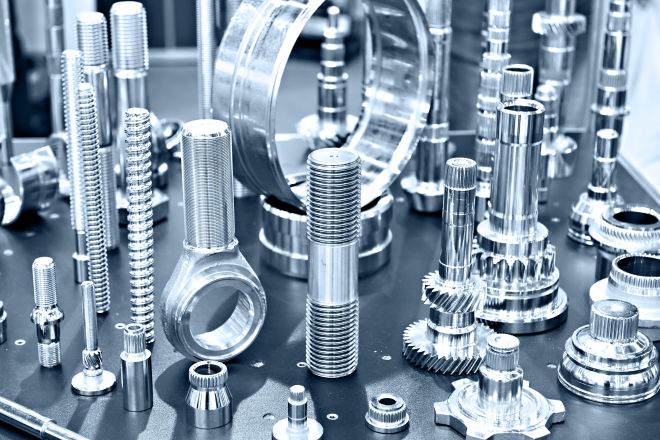

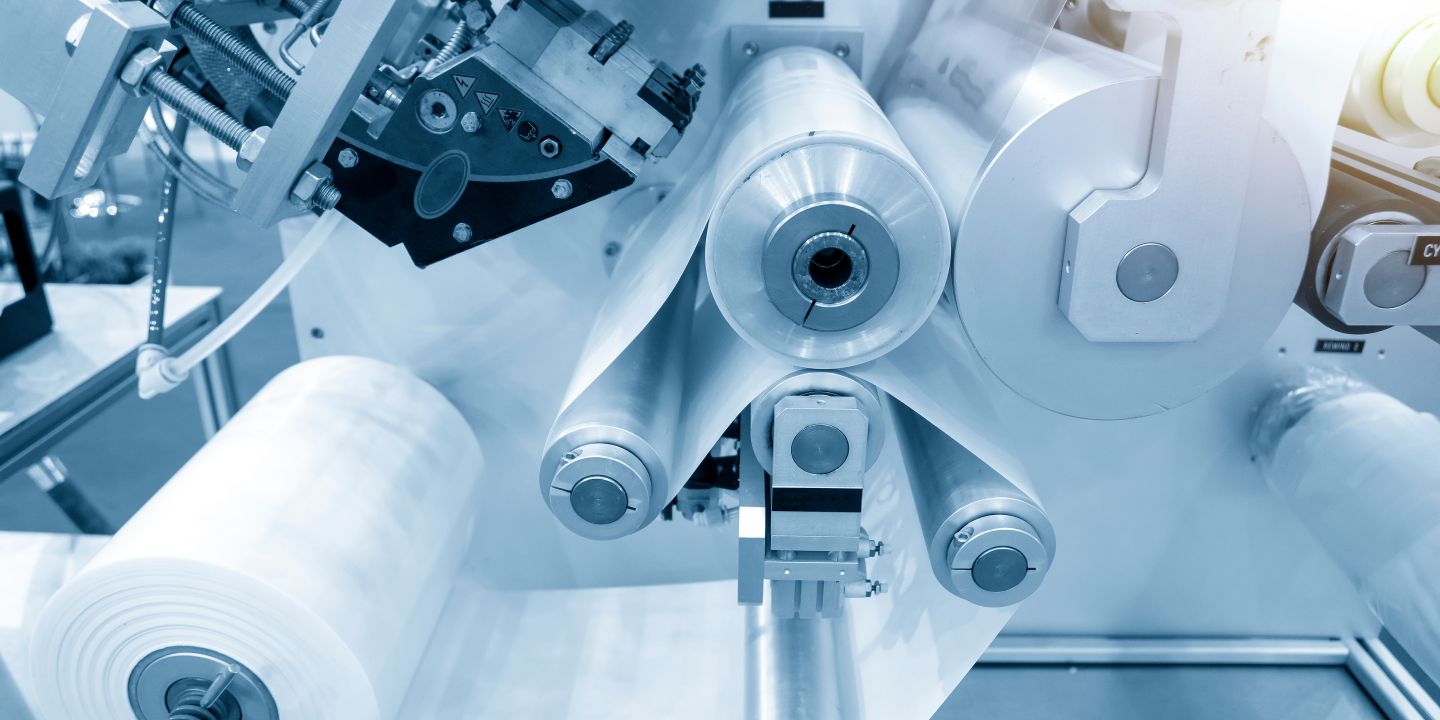

Our offer includes various packaging machines. However, our focus is on machines for filling and wrapping pasty products such as butter, including coding and the appropriate cartoning machine. We would be happy to overhaul your existing system or overhaul a used machine from our stock and adapt it to your requirements.

Regardless of whether you need a new system, want to have your existing system completely overhauled or need spare parts: we will support you in your project.

Modern design and manufacturing

Preventive maintenance

Procurement of spare parts

Overhaul of used machines

Verpatex / SERVICES

SERVICE OVERVIEW

Click on the respective headings to learn more about our services.

New machines

The focus here is on a system for filling and wrapping butter/margarine with the following performance data:

- Output: approx. 40 packages/minute

- Product weight: 50-250 grams

- Dimensions: By agreement

- Product: butter, margarine etc.

- Wrapping material: laminated aluminium foil, parchment

Retrofit

Retrofit – overhaul of used machines

In many cases it makes more sense for the operator to have his machine overhauled than to invest in a new system.

What work is carried out on a system during a retrofit?

- Renewal of all worn parts such as bearings, bolts, bushings, cam discs etc.

- Customization of functions according to customer requirements

- Update of the control according to the current stan

- Updating of the safety technology including issuing the CE declaration of conformity

- New paintwork

Retrofitting has a positive effect in many areas:

- No additional training times

- No conversion of stock spare and wear parts

- Energy & resource-saving

Inventory

Our inventory currently includes the following machines for overhaul:

- Benz & Hilgers (Benhil) dosing and wrapping machines

- Type: 8311, 8340/ Trepko XPG40, 8358 + collector 8535, 8380, 8345, 8347

- Benhil cup filling and sealing machines

- Type: 8205, 8210

- Benhil Cartoner

- Type: 8529, 8531, 8538

- Hassia thermoforming, filling and sealing machines

- Type: VAII, THL23-20

- Hoyer cup filling and sealing machines for ice cream

- Type: E80

Spare parts

We would be happy to support you in procuring spare parts, even for older machines. Due to extensive documentation of used systems, we can offer many spare and wear parts.

Thanks to re-engineering, we can redesign and, if necessary, optimize parts even without existing drawings.We have modern options such as 3D scanning and rapid prototyping at our disposal.

We would be happy to support you with preventive maintenance. To do this, we work with you to develop a service contract that increases machine productivity and minimizes downtime.